Labels & packaging play an important part of our everyday lives. They carry our food, beverages, medication and many other useful and important items. The relationship between labels and packaging and their impact on the environment can be complex. QLM has the expertise and supply chain to provide practical and easily accessible solutions that provide true results in achieving sustainability goals.

WHY do we need to change?

Exposure to considerable environmental issues, government commitments, changing consumer attitudes, global commitments and individual companies setting targets are all contributing to a change in mindset, behaviour and expectation.

We generate a lot of waste every year. Materials lost to landfill include plastics, paper, glass, metals, textiles, masonry, food and other organic materials, are resources that are going to waste. Even though the overall waste generated per person in Australia has actually declined and recovery rates have increased, overall waste generation overall continues to rise, driven by growing populations. AND our recycling rates are still way too low, even though there is considerable investment now being expended on recycling plants and infrastructure.

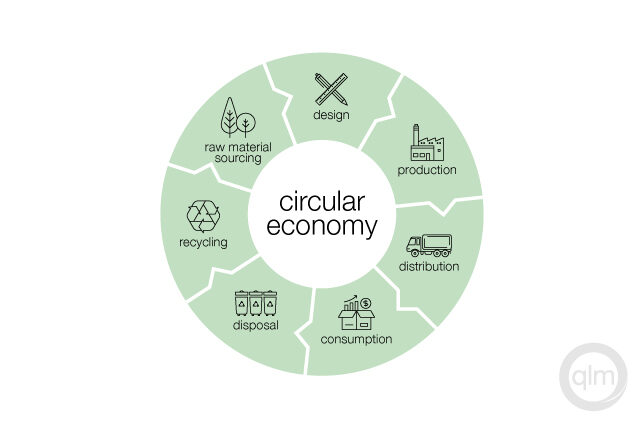

You will hear more and more about the ‘circular economy’ where we shift from take, make, use & dispose of society, to one that has a more circular approach that maintains the value of resources longer. You will also be exposed to terms like the new plastics economy, a global commitment on plastic waste where stakeholders rethink & redesign packaging, eliminate unnecessary packaging and innovate to reuse, recycle, compost. It is popularly called the “war on plastics” and is an extension of the circular economy where the goal is to keep plastics in the economy by recycling and reusing. |  |

What is sustainability and how do you achieve it?

Sustainability goals should be set and achieved through a holistic approach that considers the overall impact we have on the environment. It is necessary to consider the role of each part of the process, from raw material supply, manufacturing and logistics, to brand owners and consumers.

While many brands considered a ‘recycled’ or ‘compostable’ label to be the only or best choice, this is not accurate and should be considered amongst a range of factors. At QLM we work with the world’s leading suppliers of raw materials to ensure you get the best and most credible options to help you achieve your sustainability goals.

The 4 Rs of Sustainability

Note: there were 3 R’s: there is now an additional R as “recycling” becomes more complex and specific.

| |

Responsible sourcing starts with using a supply chain committed to achieving environmental standards and purchasing materials from an ethical and certified supply chain. Responsible sourcing incorporates the use of raw materials that come from sustainably sourced raw material suppliers and are identified by an FSC® Certification – certified by the Forest Stewardship Council ®. FSC provides Chain-of-Custody (C)OC) certifications for responsibly managed forests. Responsible sourcing can also include products made from renewable resources. QLM Label Maker’s primary raw material suppliers include: Avery Dennison & UPM Raflatac. Each supplier has FSC certification and a range of stocks suitable for achieving sustainability goals. Using products and suppliers who have these certifications enables you to demonstrate the legal and sustainable sourcing of forest products to your customers. |

| |

A reduction strategy is about using less or lightweight packaging to reduce the environmental impact and subsequent carbon footprint; or by using materials created using less resources. They include products that offer comparable or superior performance using less materials, consume less material by using thinner labels and/or improve management of production waste. From a converting and application perspective, thinner labels generally equal less raw materials and more labels on a roll (increased reel lengths) resulting in a number of time and cost efficiencies including productivity and costs benefits throughout both the converting and application processes including: less start-up, changeovers, downtime and waste during conversion on presses and equipment and reduced downtime during label application. There are also a number of waste, storage and energy benefits that can be assessed and evaluated using tools from our key raw material suppliers. If you are aiming for net zero impact and to reduce your impact on natural resources, a reduction strategy can assist in achieving this. |

| |

The term ‘recycled’ with labels and packaging incorporates products made of recycled content. These products also include products made from PCR: post consumer recycled waste. These products are significant in contributing to a ‘circular economy’ and provide significant sustainability benefits in terms of raw material usage, energy and water consumption and waste generation. Products can be partially or fully composed of recycled materials or post consumer waste and include both face stocks, adhesives and liner materials. Recycled materials are available across a range of substrates including Paper, PP and PE as well as liners. Be aware that pricing may be higher than non-recycled materials and some materials are imported with longer lead times. Major advances in some materials mean that you may already be using these materials. rDT™ is a recycled content Direct Thermal material that is already being used for ALL QLM direct thermal labels. |

| |

| The term ‘recycling’ with labels and packaging incorporates a number of different strategies: a product that is recyclable or enables recycling (eg. PET bottles), products that can be removed to enable Re-use (eg. glass bottles), labels that are biodegradable or industrially compostable and also waste recycling programs & products for label matrix and liner waste. Achieving ‘closed loop’ recycling means that labels must be easily removed during the recycling process. Labels generally are never recycled, however they are major contributors to contamination and subsequent downscaling of resources during recycling. Labels that enable recycling need to be specifically paired with the material of the base container. Eg. CleanFlake™ is designed for PET containers and recycling, whereas WashOff™ is specifically designed for glass container recycling. **BE AWARE: Biodegradable and compostable label options are actually declining in popularity as they can contribute to greater landfill and often require specific infrastructure such as industrial composting facilities in order to achieve the desired result. Some companies posit label materials as biodegradable but do not consider the interactions with inks, laminates or the base containers as to the actual benefits achievable. |

Work with us to achieve your sustainability goals

It is easy to be confused with the many options, terms and materials available. We can all play a part in achieving a more sustainable planet. Talk to us today to evaluate which options work best to achieve your sustainability goals.