By understanding labels, the end-use or application, we will guide you through the many choices available:

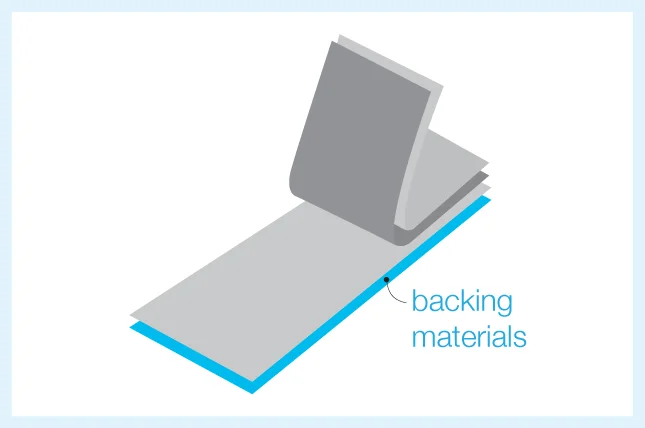

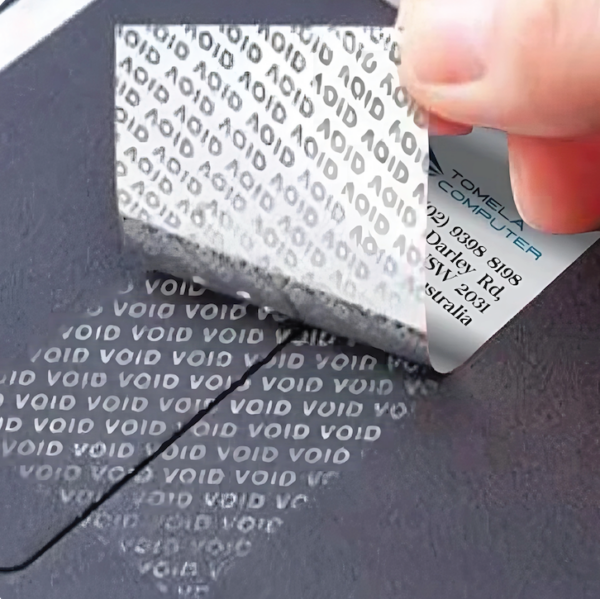

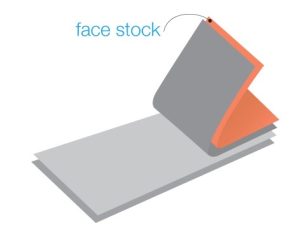

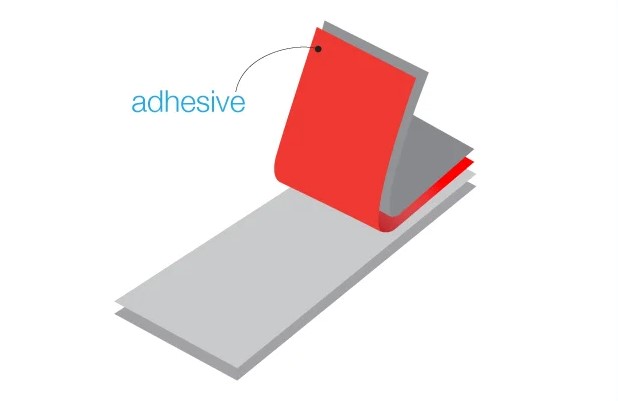

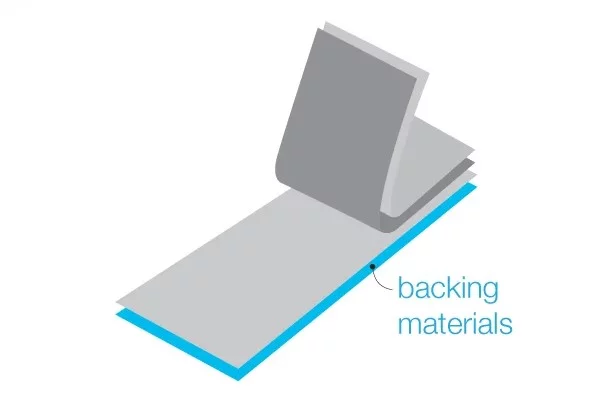

Labels have 3 parts:

- face stock

- adhesive

- backing material.

Most stocks are either a paper based or synthetic (filmic/plastic) material.

1/ Face stock:

Face Stocks come in many variations of 2 main types: Paper or Synthetic.

Read more: Synthetic labels vs paper labels

– Synthetic (or Filmic) Face Stocks

- Plastic or filmic in construction (won’t tear in both directions).

- Used where durability is required (moisture, chemical or temperature).

- Popular with bottles being recycled.

- 3 main types of synthetic material:

- PE: Polyethylene (where squeezability is required)

- PP: Polypropylene (durable and available in clear)

- PET: Polyester (used for resistance to water, oil or chemicals)

– Paper Based Face Stocks

- Made of material converted from wood to paper.

- Suitable for most dry environments.

- Very popular for fast moving items required for short term use.

- Are highly versatile, economic and achieve outstanding print results.

- Popular paper-based face stocks at QLM: Uncoated paper, Semi-gloss paper, cast coated paper, metallised paper, direct thermal paper, thermal transfer paper, wine paper

2/ Label adhesives

Initial adhesion or ‘tack’ during application affects the performance of the label during its lifespan. Poorly applied labels or the wrong choice of adhesive impacts on how your label stands up to it’s intended use.

When deciding on a label adhesive you will need to consider:

- Adhesion – 3 Options: Permanent, Removable or Repositional

- Formulation – 2 Options: Acrylic or Hotmelt

Three Options for Adhesion:

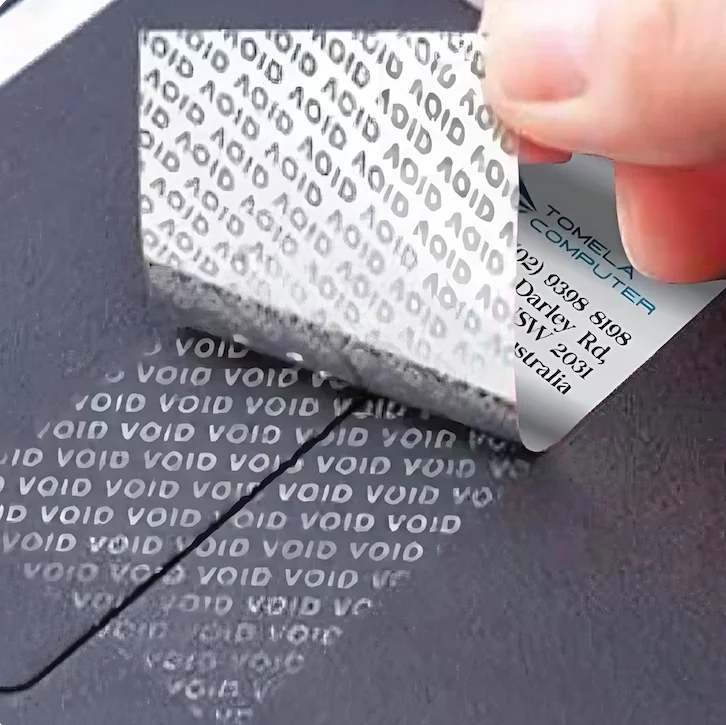

a) Permanent adhesives: are designed not to be removed (the most common adhesive)

- Can be acrylic or hotmelt formulated.

- Options for difficult surfaces (including moist or frozen objects, curved surfaces, even tyres!).

- Attempting to remove or reposition labels damages the label.

b) Removable adhesives:

- Allow long-term removability from a variety of substrates.

- Popular for laboratory applications where no residue is desired.

c) Repositional Adhesives:

- Offer short term repositionability (usually within 48 hours).

- Used when automatic labelling is difficult due to the shape of the object being labelled.

- You can remove and reposition it without noticeable damage to the face stock.

- Easy to remove directly after labelling but become permanent over time.

**SPECIAL OPTION: Food Grade Adhesives:

- Available for labels that will be applied directly to food products including dry, moist and non-fatty foodstuffs as well as for meat labelling.

Two Options for Formulation:

a) Acrylic adhesives:

- All filmic face stocks utilise an acrylic adhesive.

- Achieve excellent clarity, UV-stability and water resistance.

- Excellent tack and adhesion properties on moist or hot surfaces and are suitable for refrigerated conditions.

b) Hotmelt adhesives:

- General multi-purpose adhesive used for heat tolerant substrates, curved or moist substrates and very rough substrates.

- Very good adhesion to non-polar surfaces.

- Good low temperature performance once labelled. Especially suitable for applications where the initial adhesion and moist surface adhesion offered by dispersion adhesives are not sufficient. Also recommended for use in cold environments, particularly if the application surface is moist or if very high initial adhesion is required.

- Limitation: Heat resistance is inferior compared with acrylic adhesive.

**SPECIAL OPTION: Freezer Grade Adhesives:

- Generally, only required when applying labels to products that are frozen or at very low temperatures (not when applying to a product at room temperature that will be refrigerated or frozen).

3/ Backing material (or liner)

The backing material (or liner) for a label is usually coated with a silicon layer on the upper side (closest to the label stock adhesive) to allow the face stock to release from the backing as it is applied to the end product.

The sticker backing material choice may matter depending on whether you require clarity or visibility through the backing (such as when overprinting) or the strength needed for particular types of machine applicators.

Backing materials come in 3 main types: Glassine, Kraft or Filmic.

How Is Glassine Backing Paper Used For Labels?

- General purpose uncoated transparent backing paper.

- Comes in a range of colour and weight variations (though usually white, yellow or a faint blue).

- Used for labels being overprinted as sensors can detect gaps between labels.

What is Kraft Backing Material for Labels?

- Coated on one side and used when extra stiffness is required.

- Comes in a variety of weights and colours (white and brown).

- Used for sheeted or A4 laser labels as it maintains good rigidity when fed through laser and ink-jet printers and copiers.

When Is Filmic Backing Used In Labels?

- Comes in either clear polyester (PET) or polypropylene (PP).

- Used when the backing needs to be clear and very strong for high-speed applicators

Let’s discuss what is the best options for your labels.